office

(847) 797-5067

office

(847) 797-5067

fax (847) 729-2475

cell (847) 797-5067

virtsurf@aol.com

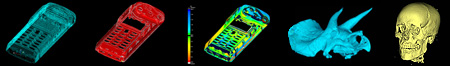

3-D Scanning

All of our work begins with the process of 3-dimensional scanning. Scanning can be accomplished in several ways depending on the parts material, size, required accuracy and desired downstream applications. The scanners we use or have access to are Computed Tomography X-ray (CT, both industrial and medical); white light optical; and fixed bed laser* process.

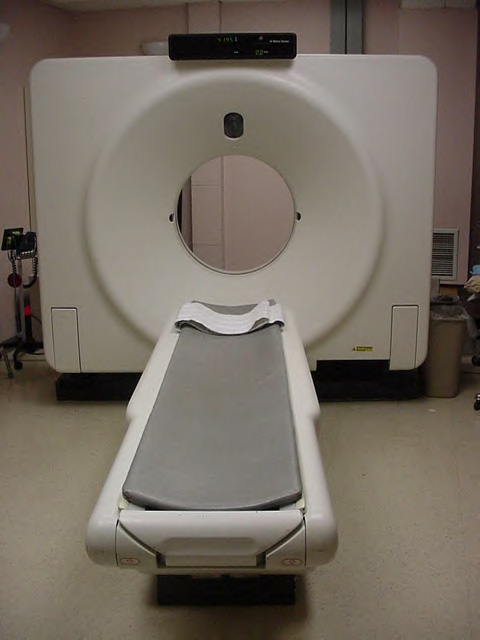

Industrial and Hospital CT

The

advantage of CT is that both visible and hidden areas are accurately

revealed with no harm to the original part. High-resolution

industrial scanners can cover a wide range of sizes and materials.

Hospital scanners are invaluable for scanning forensic and

biological entities.

White Light Scanners

These scanners provide a quick and accurate method of scanning parts either having large or small areas. The scanner progressively scans adjacent areas and, at the same time, recording registration marks to insure data continuity. White light scanners are portable providing offsite scanning in remote areas

Fixed Bed Laser

These canners consist of a traditional CMM bed with a non-contact

laser scanner replacing the touch probe. The bed records the X – Y

dimensions, the laser providing the Z dimension. Accuracy is around

+/-0.001 inches (0.0254 mm)

Portable Laser Scanner

These scanners uses a precision portable arm with laser scanning

head. The advantage is that the laser head can squeeze into areas

that fixed bed or white light scanners fail to reach. It also can be

taken to out door field locations, where the conditions are

generally not favorable for white light scanners.